Application of ESTi to Electrochemical Device Testing

By Derek L Smith PhD, Consultant - December 08, 2020

In this new series of blog posts; we will be illustrating some of the features and benefits of the innovations in Venable Instruments’ ESTi™ electrochemical device tester, beginning with wide thermal calibration. In the case of Venable Instruments’’ ESTi, thermal calibration refers the instrument’s calibrated accuracy over the instrument’s operating temperature range of 0°C to 50°C.

Voltage drift

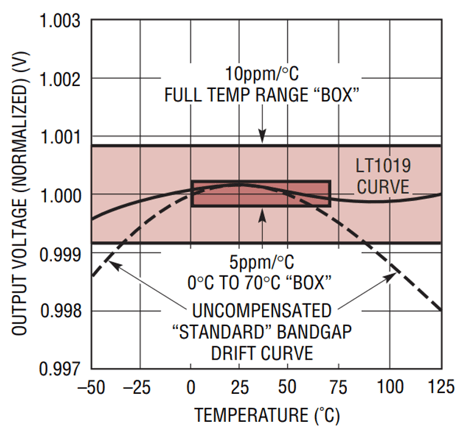

Though ICs are designed to be very stable across a wide temperature range, no device is completely stable and inert with respect to temperature variation. Note the following figure that illustrates how output Voltage of a common Voltage reference deviates slightly across a wide temperature range.

While an extreme instability or error in Voltage measurement could be regarded as a safety issue, even small Voltage offsets can induce errors in establishing figures of merit; such as Coulombic efficiency, capacity or cycle life—latter two illustrated below. Similarly, shifts in measured input or output current—particularly when repeated over many simulated life cycles—can result in marketing or performance errors with respect to commercial energy storage devices.

Lead-acid

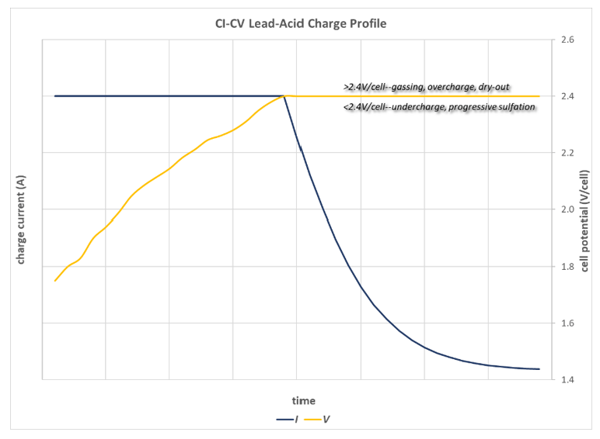

Lead-acid batteries represent nearly ancient technology when compared to the pace of modern technological progress but are still indispensable for SLI and stand-by applications. Moreover; as lead-acid batteries are concentration cells—devices whose Voltage is strongly dependent upon the concentration of the electrolyte, accuracy in potential measurement is critical to attaining full charge and measuring state of charge accurately. The most efficient charge profile for sealed lead-acid batteries involves CI-CV charging—a two-step process that begins with a constant-current phase and finishes with a constant-Voltage phase at ~2.40±0.05V until current decreases to a value equivalent to a percentage of the rated capacity. (See Figure 2, below.)

Figure 2 simulated lead-acid charge profile

A deviation or uncertainty of 50mV either way does not seem at first blush to be significant, but the chemistry is particularly sensitive to changes within this narrow band. In fact the balance is so tenuous as to pass from a condition of undercharge and advancing sulfation (so-called “memory effect”) to overcharge and dry-out within this range. In either boundary condition the life of the module is potentially and progressively lessened.

Lithium

Though lithium-based chemistry is more of an exercise in materials science, rather than continuously varying concentration of electrolyte; accurate and precise Voltage control is an independent parameter for the establishment of appropriate specifications and the optimization of a cell’s ability to perform accordingly. Now, unless the Voltage sense and regulation circuits are grossly out of calibration the intrinsic hampering effects mentioned above are not especially applicable; but, according to one developer of power-related products, certain lithium configurations do bear a significant impact from charge Voltage.

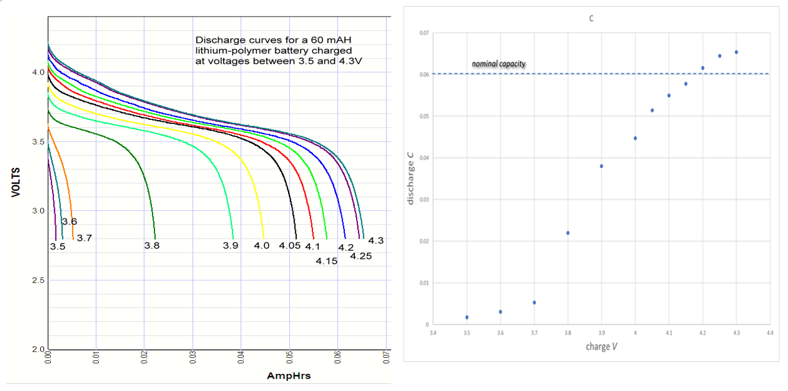

Figure 3, below, left shows that the discharge capacity of a lithium cell to a cut-off of 2.8V is highly dependent upon the charge cut-off potential. The curve on the right shows that charging to ≥4.2V will even contribute to a discharge capacity greater than the nominal value, though at a detriment to product life.1

Figure 3 illustration of lithium-based cell capacity vs. top-of-charge potential (family of curves courtesy of PowerStream[1]

Figure 3 illustration of lithium-based cell capacity vs. top-of-charge potential (family of curves courtesy of PowerStream[1]

In order to estimate the impact over the life of a cell (discussed in the next paragraph), one may note that the difference between successive 0.05-V cut-off capacities is an average of ~3.5mAh or ~5.8% of nominal capacity. Furthermore; using the function for the enhanced life cycle factor, , where Vch. is the top-of-charge potential; one can calculate the effect upon life. Normalized to cycle life at 4.2V, the reduction in life for a 50mV error is 7-8%. While these losses are not life-threatening, the discrepancies represent the likelihood that cells could be mis-specified, leading to perceived failures and customer dissatisfaction.

Multi-point thermal calibration

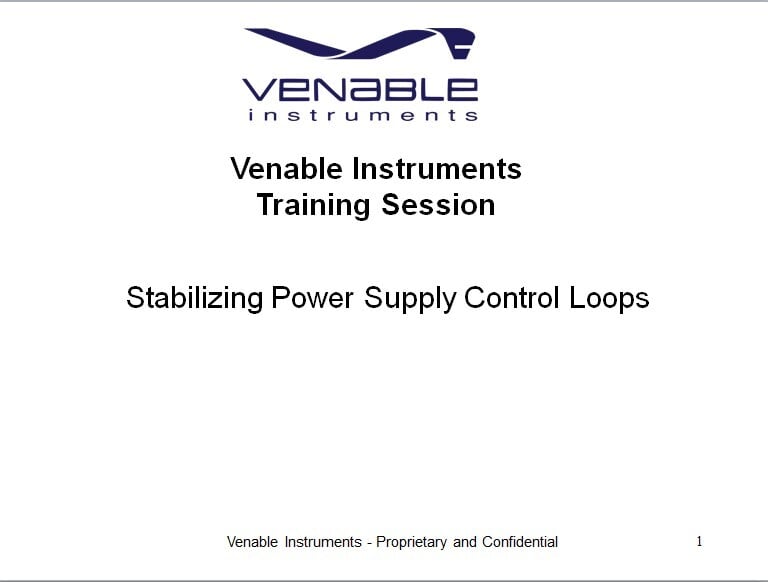

Anticipating such opportunities for characterization errors and myriad indeterminate discrepancies, Venable Instruments has devised an industry-only approach to instrument standardization: our preemptive response to potential thermal effects consists of a multi-point Voltage, current calibration process that exceeds even the bounds of the wide environmental specification offered for the ESTi line of cell testers. Note that what we are discussing is not merely stating that the instrument will operate within a laboratory or industrial environment at temperatures between 0 and 50°C but that parametric accuracy will be ensured throughout that range.

Briefly, this assurance is afforded by calibrating the instrument over the entire range of Voltage and current at three different temperatures—1°C, 27°C and 55°C—within a static thermal chamber. The calibration parameters of the control circuits, such as gain and offset, are tabulated at these three temperatures; and a curve is fit over the range to provide interpolative values for all intervening temperatures. The calibration is then checked at two thermal points—14°C and 38°C—within the range to verify that the input, output calibration is well within the specified value—0.2%FSR. Again, we are not representing the determination of a one- or even two-point calibration and subsequent application of a corrective polynomial to effect an extrapolative mathematical correction across the range of tolerable temperatures; we are establishing the conformance at three different temperature points and certifying agreement at two additional points.

Summary

The importance of Voltage and current accuracies in testing equipment can not be overstated, and some possible effects have been illustrated above. By devising and imposing such a rigorous calibration strategy, however; Venable Instruments are uniquely able to eliminate these adverse effects by providing error-free instrumentation for the testing of energy storage products that support any technological application: and this scrupulous, certifiable accuracy is rendered completely independent of temperature.

[1] “How does capacity correlate with charge Voltage for lithium ion batteries?”