Modern SMPS Control Loop Testing

By Ford Mays - May 21, 2019

As modern circuits are increasingly miniaturized and produced cost effectively, integrated circuits on a single or a few chips replace multiple discrete components. However, in discrete component circuits any point in the circuit is accessible for loop measurement. But once those points move inside a chip they are no longer accessible. This blog post provides an introduction to this topic with respect to modern switching-mode power supplies (SMPS), and links to our in-depth white paper on the subject, Practical Testing Techniques For Modern Control Loops.

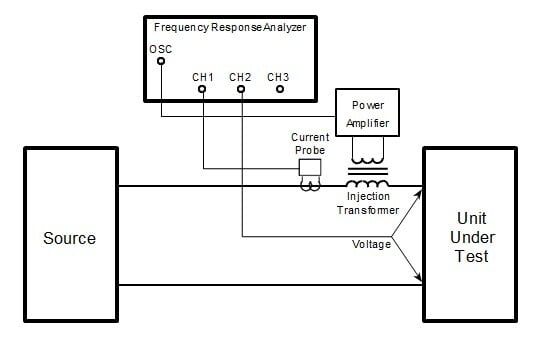

SMPS are electronic power supplies that use rapid switching to efficiently convert electrical energy from one form to another such as converting between AC and DC or changing the voltage or frequency. Whatever the application, SMPS need to be tested for their transient response, for example, how fast they respond to changes in load or line voltage. Testing for gain margin or phase margin in discrete component SMPS was achieved by loop measurement at two points:

- At the connection between the voltage error amplifier and the pulse width modulator (PWM) - but that point has been moved inside most PWM integrated circuits and is no longer accessible

- At the connection between the output of the power supply and the input of the voltage error amplifier - but this point is rapidly becoming inaccessible or invalid with the inclusion of multiple output voltages feeding a single summing node.

A PWM reduces the average power delivered by effectively chopping it up into discrete parts by turning the supply switch on and off at a fast rate. The rate (or frequency) at which the power supply must switch varies by application but the key advantage is very low power loss. When a switch is off there is practically no current, and when it is on there is almost no voltage drop across the switch – power loss as the product of current and voltage is low in either case. Compare that to the old approach of using a rheostat, for example, in the foot pedal of an old sewing machine to adjust the amount of current flowing to the motor. This was very inefficient because power was wasted as heat in the resistor of the rheostat.

PWMs are therefore integral to modern SMPS but as a result measuring for gain margin and phase margin requires a new approach. Fortunately a new technique has been developed for modern SMPS control loop testing on virtually any PWM chip. The white paper Practical Testing Techniques for Modern Control Loops describes the technique and gives examples of how to apply it to various types of integrated circuits.

Read Related Blog Posts:

Testing and Stabilizing Feedback Loops in Today's Power Supplies